ATD Blog

3D Printing in Training

Wed Feb 13 2013

Thanks for having me back to the ASTD Learning Technologies blog! You can find the first post in my series here, which provides context for this post. Essentially, I’m writing over the next few weeks on emerging technologies, their application in training, and relatively simple ways to start experimenting with them. First up? Let’s take a look at 3D printing.

The emergence of 3D printing was center stage at this year’s Consumer Electronics Show (CES) in January—the biggest circus (er, conference) of its kind in North America. A company called Cubify took home Best Emerging Tech award for its latest 3D printer, the CubeX, which looks more like an espresso machine than a high tech device. Only last week, scientists at the University in Edinburgh printed human embryonic stem cells, claiming their work paved the way for us to 3D print our own organs. In other words, we’re on the verge of going science fiction.

Basics of 3D Printing

The process behind 3D printing is essentially taking a 3D digital model, created with modeling software, and building the model in real life, layer by layer. Printers range from consumer-level “desktop” options like CubeX (which range in price from $500 to $4,000) to industrial models that can cost in the millions.

The material used to print the objects is most commonly plastic, and it gets fancier from there to include ceramics, resins, metals—and if you’re a researcher in Edinburgh, you can add organic matter to the list. As a general rule, the more precise and polished you want your model to be, the more it will cost you.For instance, a 4 x 4 x 4 inch model in a simple plastic will likely run you about $230; this cost doubles if you use a silver-coated resin. And the colors, well, they are endless.

Potential for Training

When I read about 3D printing, the word “disruptive” is often included in the description. Manufacturing, retail, dentistry, prosthetics, and fashion are some of the industries that call 3D printing a game-changer. There’s clearly a lot of hype. Dare we add training to the mix?

My answer to that is…depends on your objectives. The idea of 3D printing naturally evokes the use of 3D simulations for technical training, such as machinery operation, safety, and even science training for the pharmaceutical industry. Generally, simulations are used to give learners high-quality representations of objects or environments that are otherwise difficult to see or access.

Now, imagine being able to take elements of these simulations into the physical world, to let learners touch and physically interact with them. What might this do for learning impact? Well, for one, some evidence suggests that multimodal learning —meaning the provision of visual (image-based), auditory, reading-writing, and kinesthetic (hands on) content—is preferred by many learners and may increase overall retention. So exploration of 3D models may nicely augment your current training program to create a truly multimodal experience.

You can also imagine the benefit that comes with constant access. Consider situations where learners need to purposefully enter a digital 3D simulation. A physical object that is readily available and always visible certainly has the potential to increase learner engagement. For example, if you are a sales person for a high tech, sophisticated product, a 3D model of the product in your home office could greatly enhance your comfort level and your confidence to describe its features to customers.

That said, I reiterate that 3D printing only seems to make sense in select cases. Let me suggest the following conditions:

increased retention of the object’s features or associated processes will have an impact on organizational goals

the object(s) are prohibitively expensive or too big/small to provide an original

your object can be effectively modeled in dimensions less than 7 x 8.5 x 8.5 inches (most 3D printing services will not go much bigger than this).

Executing 3D Printing Projects

So now that you’ve identified a potential object, let’s talk about execution. The first thing you need to do is obtain a model. The file type that typically is required by most 3D printers is called an .stl file (which stands for STereoLithography).

I’m guessing most of you, like myself, have no idea how to create viable .stl files of 3D models. So let me suggest you outsource this part. If you already work with 3D animation studios, they should be able to help you here. If you need a really accurate model, you might want to consider a specialized 3D modeling service. Or if you want to go quick and dirty, you can stake out recent industrial design graduates looking for contract work. Just make sure that your modeler knows what 3D printer and service you intend to use; this has implications for structure and color design.

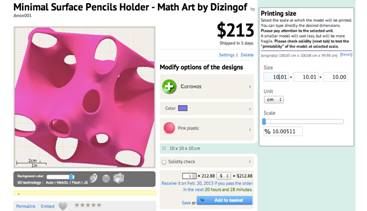

The easiest way to get this model printed is to use a cloud-based 3D printing service such as Sculpteo. I grabbed an open source .stl file of a pencil holder and uploaded it to Sculpteo. It literally took 5 minutes to choose my material and color and get it ready to print (see screenshot below). It felt like online shopping. My only other advice is leave yourself enough time to try printing just one object first, a test run of sorts, while you’re getting comfortable with the technology.

So, there you have it. It’s relatively easy to start experimenting with 3D printing—this seemingly futuristic technology. More important, I would love to know if you have already tried 3D printing in a learning context and your experience with the technology, or the potential for this technology to be employed in your organization. Drop me a comment or a tweet if you want to chat about it. Otherwise, I’ll see you next week with my next post in this series.

You've Reached ATD Member-only Content

Become an ATD member to continue

Already a member?Sign In