ATD Blog

Pay No Attention to the Man Behind the Curtain! Operationalizing Training in Manufacturing

Wed Mar 20 2019

Toward the end of The Wizard of Oz, Dorothy, Lion, Tin Man, and Scarecrow finally make it to see the wizard. Dorothy and her journey mates watch an intimidating, oversized green face (the wizard) speak powerfully while flames spew up at each inflection of the voice. Then the unthinkable happens: Toto, her faithful dog, moves the curtain. Viewers realize the magical, powerful wizard was no more than one man operating a bunch of levers and controls.

In The Wizard of Oz, the man behind the curtain successfully operates an entire economy made of yellow brick roads, talking animals, and magic witches by perception. Similarly, many successful training departments work with minimal resources—one or two people operating levers and creatively using controls to create and manage an entire operation.

As training practitioners in manufacturing, how can we support our organizations while operationalizing the training and development function with minimal resources? Before we answer this question, let’s take a look at the problem we face: the current state of labor.

Of the top trends in our industry for 2019, the shortage of skilled and unskilled labor resonates the loudest. With nearly a half-million open positions and unemployment at an all-time low, this shortage threatens to derail forward progress unless companies are willing to invest in their existing workforce.

Technology and automation add complexity to the already dynamic issue. Jobs are being redefined, as many plants leverage the digital transformation. Repetitive or manual tasks are being replaced by automation. While this removes repetitive data collection, it magnifies the growing need for problem solving and analytic skills. What’s more, it increases the need for adequate training.

As we begin to manufacture more products, there is one constant. The world is changing; people order products, want them customized, and need them to arrive quicker than ever expected before. Adding to this issue, there is consistent pressure to do more with less. Globalization and increased competition are a couple of the many factors adding pressure to keep the bottom line low but profit margins high.

How can we make quality products for customers while keeping costs low? In manufacturing, most companies value a dollar today more than a dollar tomorrow. Training costs money today, while not training costs money tomorrow. This disconnect leaves many training departments in limbo when trying to get buy-in from top executives.

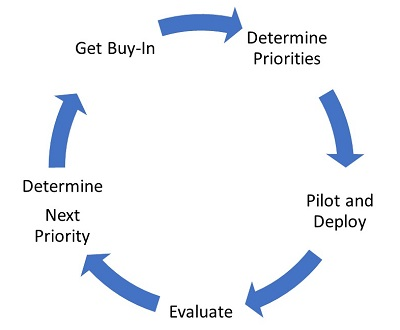

This is the first post in a two-part series related to developing the foundation to a holistic, systematic training program in manufacturing. Step 1 is to get buy-in.

As with any initiative, you need to create a sense of urgency. But what topics are most important? Who will facilitate all this training? Who holds most of the knowledge and who decides when additional resources are granted? These can be tough questions to answer, as not all power is held by job titles. There are a million variables outside of your control. That said, you need to know who can expand your budget, increase your resources, and very simply say “yes” to helping set the stage to operationalize training and remove your workplace roadblocks.

These questions are a quick way to determine who can help push your training initiative:

Can this person influence other leaders?

Does this individual run functions that directly impact key performance indicators of an organization?

Does this person set strategy?

Does this person have the power to say “yes”?

Does this person sign checks?

If you can answer “yes” to these questions, that person is a key decision maker who you want behind your cause and engaged in pushing priorities. Keep in mind that key decision makers may or may not have an official corresponding title, so you may have to think outside the box when you start your detective work.

Bottom line: When resources are limited, buy-in is a priceless lever that training practitioners should use as a catalyst for success. What are some additional ways to identify key decision makers to help training practitioners receive buy-in?