TD Magazine Article

Member Benefit

Which Performance Issues Are Impeding Progress?

Content

Process mapping enables companies to identify—and eliminate—faulty processes and performance gaps.

Process mapping enables companies to identify—and eliminate—faulty processes and performance gaps.

Thu Jun 01 2023

Content

Organizations can face a host of performance challenges where gaps between desired and actual performance are worth closing. Organizations don't typically face lone performance gaps. Instead, the gaps often travel in "wolf packs"—and each gap in the pack can arise from multiple interacting causes in the workplace environment and individual performers. Faulty workplace processes can produce many of those gaps. In addition, process problems can occur alongside other causes of performance gaps.

Organizations can face a host of performance challenges where gaps between desired and actual performance are worth closing. Organizations don't typically face lone performance gaps. Instead, the gaps often travel in "wolf packs"—and each gap in the pack can arise from multiple interacting causes in the workplace environment and individual performers. Faulty workplace processes can produce many of those gaps. In addition, process problems can occur alongside other causes of performance gaps.

Content

Process mapping is a performance improvement technique that positively affects organizational effectiveness. Companies that have engineered streamlined and efficient processes have better capacity to meet their missions and strategic organizational goals to serve their customers than companies with faulty processes. Adding process mapping to your performance improvement tool set can help your organization better identify and address multiple, simultaneous performance gaps.

Process mapping is a performance improvement technique that positively affects organizational effectiveness. Companies that have engineered streamlined and efficient processes have better capacity to meet their missions and strategic organizational goals to serve their customers than companies with faulty processes. Adding process mapping to your performance improvement tool set can help your organization better identify and address multiple, simultaneous performance gaps.

Causes and solutions

Content

Process re-engineering. Process improvement. Process management. Process automation . Oh my. You will face multiple types of organizational process improvement techniques, which creates an alphabet soup of related terminology and confusion for talent development professionals and organizations alike.

Process re-engineering. Process improvement. Process management. Process automation. Oh my. You will face multiple types of organizational process improvement techniques, which creates an alphabet soup of related terminology and confusion for talent development professionals and organizations alike.

Content

As the term implies, process mapping is a visual approach for fixing existing processes that aren't meeting stakeholder expectations. Using the technique, the TD team works with the work group to map out a given organizational process from start to finish. Owing to the level of effort associated with the technique, the process selected for improvement should be mission critical—one that significantly affects the organization's ability to serve customers.

As the term implies, process mapping is a visual approach for fixing existing processes that aren't meeting stakeholder expectations. Using the technique, the TD team works with the work group to map out a given organizational process from start to finish. Owing to the level of effort associated with the technique, the process selected for improvement should be mission critical—one that significantly affects the organization's ability to serve customers.

Content

In his case study, Applying Process Design Principles, Daniel Madison shares five lenses through which to view processes: frustration, time, cost, quality, and customer. Each offers a unique perspective of value to consider.

In his case study, Applying Process Design Principles, Daniel Madison shares five lenses through which to view processes: frustration, time, cost, quality, and customer. Each offers a unique perspective of value to consider.

Content

If your organization has well-defined, measured, controlled, and optimized processes, then it is probably collecting the necessary data to use the time, quality, and cost lenses. In contrast, if the processes are unpredictable, poorly controlled, or managed reactively, then the company may benefit from using the frustration and customer lenses.

If your organization has well-defined, measured, controlled, and optimized processes, then it is probably collecting the necessary data to use the time, quality, and cost lenses. In contrast, if the processes are unpredictable, poorly controlled, or managed reactively, then the company may benefit from using the frustration and customer lenses.

Content

Process mapping enables organizations to conduct a broad-ranging investigation that cuts through multiple departments. Each of the departments can act as a silo, where the people working on a process can be largely unaware of how their work affects downstream departments.

Process mapping enables organizations to conduct a broad-ranging investigation that cuts through multiple departments. Each of the departments can act as a silo, where the people working on a process can be largely unaware of how their work affects downstream departments.

Content

During a process-mapping workshop, chart the complete procedure and identify the disconnects where individual activities that constitute the process are broken. Each of the disconnects produces its own performance gap, which lends itself to its own analysis. Having identified the disconnects, the work group can then specify feasible solutions to address them. Working in that way enables the TD team to address a pack of performance gaps plaguing a given process.

During a process-mapping workshop, chart the complete procedure and identify the disconnects where individual activities that constitute the process are broken. Each of the disconnects produces its own performance gap, which lends itself to its own analysis. Having identified the disconnects, the work group can then specify feasible solutions to address them. Working in that way enables the TD team to address a pack of performance gaps plaguing a given process.

Content

In addition to addressing multiple performance gaps at once, this performance improvement technique can reduce the frustrations associated with broken processes. Disconnects can cause stakeholders pain and lead to frustration as they cope with errors, rework, delays, and cost overruns. Working together with the people who complete the process enables the TD team to produce a shared mental model of the process across the organization. Further, working together to specify and prioritize solutions promotes organizational buy-in for the changes the solutions will bring.

In addition to addressing multiple performance gaps at once, this performance improvement technique can reduce the frustrations associated with broken processes. Disconnects can cause stakeholders pain and lead to frustration as they cope with errors, rework, delays, and cost overruns. Working together with the people who complete the process enables the TD team to produce a shared mental model of the process across the organization. Further, working together to specify and prioritize solutions promotes organizational buy-in for the changes the solutions will bring.

Conduct the workshops

Content

Process mapping can include three workshops that focus on planning, mapping the current process, and determining what the improved process will be.

Process mapping can include three workshops that focus on planning, mapping the current process, and determining what the improved process will be.

Content

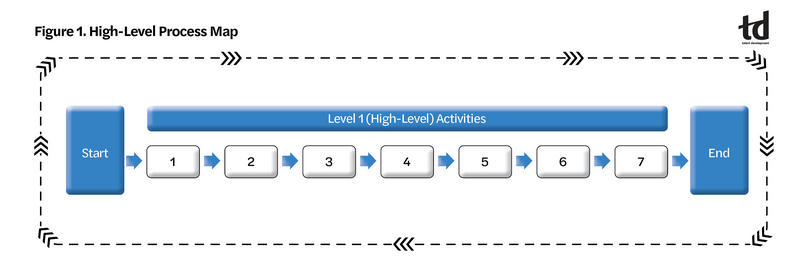

During the planning workshop, the TD team and client (the business owner who sponsors the process-mapping effort) create a high-level representation of the selected process, typically around seven or so major—or level 1—activities (see Figure 1). Map the current process by identifying where it starts and ends as well as the major activities between those two points.

During the planning workshop, the TD team and client (the business owner who sponsors the process-mapping effort) create a high-level representation of the selected process, typically around seven or so major—or level 1—activities (see Figure 1). Map the current process by identifying where it starts and ends as well as the major activities between those two points.

Content

The TD team also collaborates with the client to select up to a dozen workshop participants. Ideally, the participants will comprise representatives of all people and groups who complete the process and are affected by it. The client, any major stakeholders, and your facilitation team will use this workshop to align on client responsibilities to sponsor the implementation of process solutions and support changes they will bring to the organization and its culture.

The TD team also collaborates with the client to select up to a dozen workshop participants. Ideally, the participants will comprise representatives of all people and groups who complete the process and are affected by it. The client, any major stakeholders, and your facilitation team will use this workshop to align on client responsibilities to sponsor the implementation of process solutions and support changes they will bring to the organization and its culture.

Map the as-is state

Content

After the planning workshop, TD uses the high-level process map to map the "as-is" state. Here, you will represent what's currently happening and identify stakeholder success criteria. Then, starting with the first level 1 activity, the facilitator will guide participants in collaborating to map the process the way they currently perform it. Working together, detail each activity in the level 1 map, breaking down larger activities into more detailed steps.

After the planning workshop, TD uses the high-level process map to map the "as-is" state. Here, you will represent what's currently happening and identify stakeholder success criteria. Then, starting with the first level 1 activity, the facilitator will guide participants in collaborating to map the process the way they currently perform it. Working together, detail each activity in the level 1 map, breaking down larger activities into more detailed steps.

Content

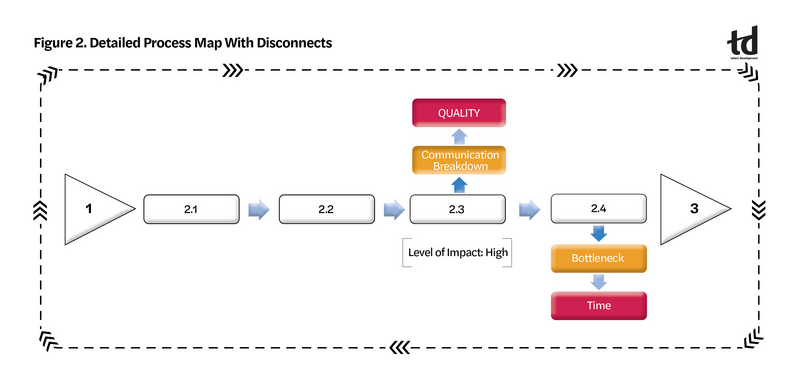

Next, identify the process disconnects that cause stakeholder pain points. For example, a communication breakdown could occur at the second major activity in the process, resulting in a quality pain point. Or a bottleneck exists at the fourth activity, causing a time pain point. It helps to frame those events by identifying the beginning and endpoints—or triggers—for each level 2 activity. That way, you will identify process disconnects and the pain points they cause for stakeholders, along with rating their level of impact (see Figure 2).

Next, identify the process disconnects that cause stakeholder pain points. For example, a communication breakdown could occur at the second major activity in the process, resulting in a quality pain point. Or a bottleneck exists at the fourth activity, causing a time pain point. It helps to frame those events by identifying the beginning and endpoints—or triggers—for each level 2 activity. That way, you will identify process disconnects and the pain points they cause for stakeholders, along with rating their level of impact (see Figure 2).

Redesign the 'to-be' process

Content

Your team begins to redesign the process in the "to-be" workshop. Start by reviewing the maps and revising them to streamline the process. Next, participants brainstorm solutions for all the remaining identified disconnects.

Your team begins to redesign the process in the "to-be" workshop. Start by reviewing the maps and revising them to streamline the process. Next, participants brainstorm solutions for all the remaining identified disconnects.

Content

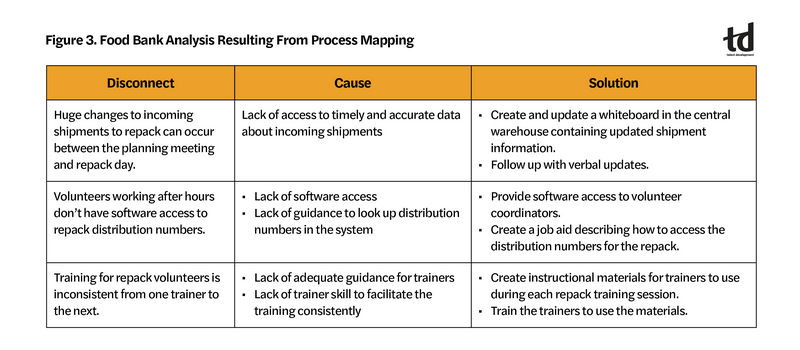

For example, a statewide food bank wanted to improve the process it used for repacking donated and stored food items for distribution to customers and satellite locations. Participants used a process-mapping approach that enabled the organization to identify multiple disconnects and specify solutions for each. Figure 3 presents several examples from the numerous disconnects and solutions the participants identified.

For example, a statewide food bank wanted to improve the process it used for repacking donated and stored food items for distribution to customers and satellite locations. Participants used a process-mapping approach that enabled the organization to identify multiple disconnects and specify solutions for each. Figure 3 presents several examples from the numerous disconnects and solutions the participants identified.

Content

After participants have exhausted all solutions, your team rates them based on potential benefit and effort and prioritizes them. Afterward, specify the initial implementation steps for the highest-priority solutions. Also determine how the implementation effort will coordinate with the change management effort as the solutions move ahead.

After participants have exhausted all solutions, your team rates them based on potential benefit and effort and prioritizes them. Afterward, specify the initial implementation steps for the highest-priority solutions. Also determine how the implementation effort will coordinate with the change management effort as the solutions move ahead.

After the workshops

Content

When the workshops are completed, the heavy lifting to implement the solutions and support change throughout the organization remains. Unfortunately, companies often fail to implement planned solutions. They also don't manage the changes that the solutions will produce in the company.

When the workshops are completed, the heavy lifting to implement the solutions and support change throughout the organization remains. Unfortunately, companies often fail to implement planned solutions. They also don't manage the changes that the solutions will produce in the company.

Content

In his Harvard Business Review article, "Change Management Needs to Change," Ron Ashkenas notes that "As a recognized discipline, change management has been in existence for over half a century. Yet despite the huge investment that companies have made in tools, training, and thousands of books (over 83,000 on Amazon), most studies still show a 60-70% failure rate for organizational change projects—a statistic that has stayed constant from the 1970's to the present."

In his Harvard Business Review article, "Change Management Needs to Change," Ron Ashkenas notes that "As a recognized discipline, change management has been in existence for over half a century. Yet despite the huge investment that companies have made in tools, training, and thousands of books (over 83,000 on Amazon), most studies still show a 60-70% failure rate for organizational change projects—a statistic that has stayed constant from the 1970's to the present."

Content

Integrating project management and change management strategies can increase the odds for successful implementation. As part of the to-be workshop, participants settle on the initial steps the organization will take to implement the prioritized solutions. During implementation, the solution teams will need to continue communicating with organizational leadership to:

Integrating project management and change management strategies can increase the odds for successful implementation. As part of the to-be workshop, participants settle on the initial steps the organization will take to implement the prioritized solutions. During implementation, the solution teams will need to continue communicating with organizational leadership to:

Content

Gain funding, resources, and release time for creating, implementing, and sustaining the solutions.

Gain funding, resources, and release time for creating, implementing, and sustaining the solutions.

Content

Report on the status of those efforts, along with any emerging barriers or project risks.

Report on the status of those efforts, along with any emerging barriers or project risks.

Content

Deploy the improved process and solutions.

Deploy the improved process and solutions.

Content

Formulate maintenance and continuous improvement strategies for the improved process and implemented solutions.

Formulate maintenance and continuous improvement strategies for the improved process and implemented solutions.

Content

To ensure process mapping succeeds, leadership, process owners, and solution owners should work together to coordinate change management efforts. That is where a change management plan will help. Newly implemented solutions will change organizational roles and the way that people perform their jobs. Due to the scary nature of such changes, change management efforts must ensure both leadership and participant support—from the top down and the bottom up.

To ensure process mapping succeeds, leadership, process owners, and solution owners should work together to coordinate change management efforts. That is where a change management plan will help. Newly implemented solutions will change organizational roles and the way that people perform their jobs. Due to the scary nature of such changes, change management efforts must ensure both leadership and participant support—from the top down and the bottom up.

Content

Top-down support includes materials for building awareness, letting people try out the new solutions (prototypes), and building credible responses to questions about "What's in it for me?" Bottom-up support means collaborating with the people who will be using the solutions. That means involving them in specifying requirements, reviewing and testing prototypes, and testing rollout versions of the solutions.

Top-down support includes materials for building awareness, letting people try out the new solutions (prototypes), and building credible responses to questions about "What's in it for me?" Bottom-up support means collaborating with the people who will be using the solutions. That means involving them in specifying requirements, reviewing and testing prototypes, and testing rollout versions of the solutions.

Build the business case for process mapping

Content

With change often comes uncertainty, resistance, and fear. At the organizational level, introducing process mapping requires a change in people's mindsets and the way they approach problem solving. The implemented solutions arising from process mapping workshops will bring further changes to the organization.

With change often comes uncertainty, resistance, and fear. At the organizational level, introducing process mapping requires a change in people's mindsets and the way they approach problem solving. The implemented solutions arising from process mapping workshops will bring further changes to the organization.

Content

To institute process mapping within the company, building a business case can help you bring awareness to the need for change, ensure alignment on key decisions, and gain influence for adoption. A business case can likewise help dispel common process-mapping myths by providing transparency on expectations and anticipated outcomes.

To institute process mapping within the company, building a business case can help you bring awareness to the need for change, ensure alignment on key decisions, and gain influence for adoption. A business case can likewise help dispel common process-mapping myths by providing transparency on expectations and anticipated outcomes.

Content

Select a mission-critical process to improve. With new initiatives, leaders often aim for quick wins to slowly build momentum and support. However, with process mapping, it is far more effective to focus on improving a high-impact, high-return process first.

Select a mission-critical process to improve. With new initiatives, leaders often aim for quick wins to slowly build momentum and support. However, with process mapping, it is far more effective to focus on improving a high-impact, high-return process first.

Content

Garner leadership support and buy-in. Communicate the benefits of process mapping by sharing the anticipated outcomes for improving the selected process and how it will positively affect stakeholders. While you cannot calculate the return on investment at this stage, you can estimate it and convey the risk of sticking with the status quo. Another tactic to garner buy-in is to showcase success stories. Provide examples of the results other businesses have had with process mapping or create short case studies to highlight successes.

Garner leadership support and buy-in. Communicate the benefits of process mapping by sharing the anticipated outcomes for improving the selected process and how it will positively affect stakeholders. While you cannot calculate the return on investment at this stage, you can estimate it and convey the risk of sticking with the status quo. Another tactic to garner buy-in is to showcase success stories. Provide examples of the results other businesses have had with process mapping or create short case studies to highlight successes.

Content

Set expectations and negotiate playground rules. You can ensure everyone is on the same page by setting expectations with leadership and process improvement participants. Detail the project purpose, anticipate timelines, and identify the required resources. As you move forward, negotiate those items with leadership, gain consensus, and use your business case to build out a more in-depth project plan.

Set expectations and negotiate playground rules. You can ensure everyone is on the same page by setting expectations with leadership and process improvement participants. Detail the project purpose, anticipate timelines, and identify the required resources. As you move forward, negotiate those items with leadership, gain consensus, and use your business case to build out a more in-depth project plan.

Content

Gaining leadership agreement on workshop playground rules is also essential for success. While those are rules participants will follow, the leadership must agree to live by them and to introduce them in the first workshop. That should include communication protocols and how the mapping team will create a safe, inclusive environment to discuss ideas and frustrations as well as voice opinions. Leadership should also set expectations for how to handle feedback on the mapping process and changes to the project plan.

Gaining leadership agreement on workshop playground rules is also essential for success. While those are rules participants will follow, the leadership must agree to live by them and to introduce them in the first workshop. That should include communication protocols and how the mapping team will create a safe, inclusive environment to discuss ideas and frustrations as well as voice opinions. Leadership should also set expectations for how to handle feedback on the mapping process and changes to the project plan.

Content

Decide who should facilitate process-mapping efforts. The facilitator is one of the most crucial roles in process mapping. They need to effectively use process-mapping techniques, tools, and technology. They likewise must ensure participants follow the established workshop rules and that participation is inclusive and fair—without a "squeaky wheel" monopolizing the conversation.

Decide who should facilitate process-mapping efforts. The facilitator is one of the most crucial roles in process mapping. They need to effectively use process-mapping techniques, tools, and technology. They likewise must ensure participants follow the established workshop rules and that participation is inclusive and fair—without a "squeaky wheel" monopolizing the conversation.

Content

There are three main options for facilitation. When evaluating each, consider the feasibility, cost, as well as the organization's resources and needs. The first option is to build internal process-mapping expertise within the TD function. That puts TD in the driver's seat and enables you to holistically manage the project within the team's portfolio of performance initiatives.

There are three main options for facilitation. When evaluating each, consider the feasibility, cost, as well as the organization's resources and needs. The first option is to build internal process-mapping expertise within the TD function. That puts TD in the driver's seat and enables you to holistically manage the project within the team's portfolio of performance initiatives.

Content

Another option is to partner with a vendor. Doing so can be beneficial if the organization lacks expertise in process mapping or does not have the staffing resources to dedicate to the project. Working with a vendor is typically more costly but can provide a fresh, outsider perspective. You can also construct the vendor contract to support a technology transfer—the organization works with the vendor using its approach to build process-mapping skills and tools, and then the vendor coaches the organization as it uses the vendor's approach to map a process.

Another option is to partner with a vendor. Doing so can be beneficial if the organization lacks expertise in process mapping or does not have the staffing resources to dedicate to the project. Working with a vendor is typically more costly but can provide a fresh, outsider perspective. You can also construct the vendor contract to support a technology transfer—the organization works with the vendor using its approach to build process-mapping skills and tools, and then the vendor coaches the organization as it uses the vendor's approach to map a process.

Content

The final option is to partner with your organization's quality improvement and IT groups to support process-mapping efforts. This method works well when those teams have the time and expertise to facilitate process improvement workshops. However, it won't work well if the groups either don't possess the facilitation expertise or the release time to partner with the TD function.

The final option is to partner with your organization's quality improvement and IT groups to support process-mapping efforts. This method works well when those teams have the time and expertise to facilitate process improvement workshops. However, it won't work well if the groups either don't possess the facilitation expertise or the release time to partner with the TD function.

Content

Select the mode for the process-mapping workshop. The business case should detail the approach you plan to use for the workshops, whether they are in person, virtual, or a hybrid variation. Each has its pros and cons and requires different types of resources and facilitation roles.

Select the mode for the process-mapping workshop. The business case should detail the approach you plan to use for the workshops, whether they are in person, virtual, or a hybrid variation. Each has its pros and cons and requires different types of resources and facilitation roles.

Content

For virtual workshops, evaluate and select the most appropriate meeting platform and collaboration tools to use. For in-person meetings, assess available conference rooms or meeting spaces, room configuration options, and travel considerations. In the business case, document your recommendations and required resources.

For virtual workshops, evaluate and select the most appropriate meeting platform and collaboration tools to use. For in-person meetings, assess available conference rooms or meeting spaces, room configuration options, and travel considerations. In the business case, document your recommendations and required resources.

Content

Now that you know about process mapping and its value for increasing organizational capability, you can face your next wolf pack with confidence.

Now that you know about process mapping and its value for increasing organizational capability, you can face your next wolf pack with confidence.